While the energy sector has been experiencing significant changes these past few years, fossil fuels as a source of energy aren’t going away any time soon.

As a result, peripheral markets continue to stay relevant and thrive.

In 2020, for instance, the global oil storage market was valued at approximately $12.2 billion.

Handling a material that keeps the gears of humanity running is, naturally, not a business that can afford to make mistakes.

The nature of the material, however, presents some risks.

CHALLENGE

The biggest risk of handling fossil fuels is that they are liquid.

Toxic, flammable, volatile liquid, but liquid nonetheless.

Did you ever arrived at your favorite picnic spot only to discover that sauce has leaked all over the insides of your bag?

Than you know that storing liquids is trickier than it sounds.

Fuel leaking from its storage tank is significantly more dangerous than your surplus salad sauce, and serious safety measures must always be in place to prevent it.

But if all fails and a leak does occur, immediate detection and appropriate response are necessary to avoid a disaster.

The problem is that fuel isn’t stored in small, individual storage tanks that an employee can comfortably keep a watchful eye on at all times.

It is stored in a great multitude of tanks, often underground. To that end, detection requires more than mere vigilance. It requires automation.

PARTNER

RAZRLAB is a software and hardware developer with ample experience in communications, distribution, security, facility management, and financial services.

In the past 14 years, it has worked on multiple high-profile IoT projects in Africa and the Middle East.

One such project was for its client in Jebel Ali, Dubai. The client was facing this exact problem, and RAZRLAB rose to the challenge.

SOLUTION

The solution RAZRLAB came up with was to place a sensor over the fuel tank to accurately and continuously monitor fuel levels via guided wave radar technology.

Any deviation from the normal amount, dictated by routine fuel usage and tank refills, will immediately be registered and reported for analysis and inspection.

This also includes sudden drops in fuel levels, which indicate theft.

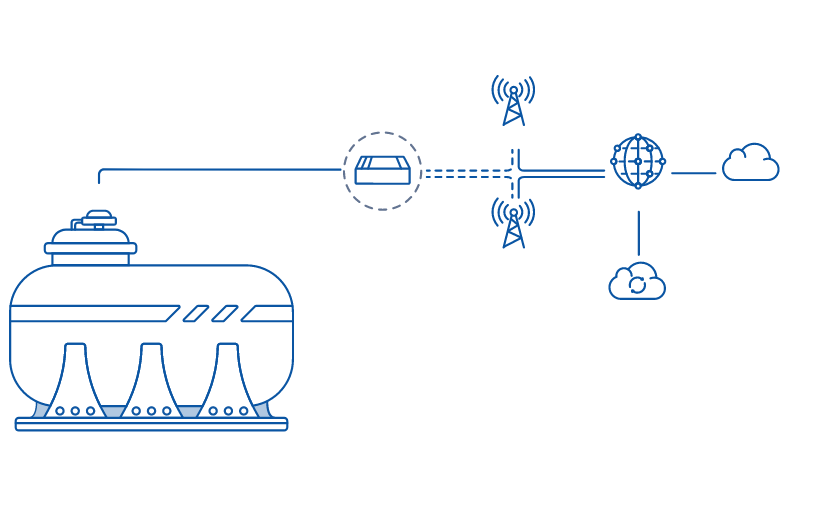

This data is then relayed to a custom RAZR cloud platform with the help of Teltonikas TRB245 industrial cellular gateway, connected to the sensor via a via RS485 interface.

This sturdy and compact model was specially designed for industrial applications and helps facilitate connectivity in challenging environments.

It does not even need cumbersome cables and additional hardware, thereby keeping infrastructure complexity to a minimum.

This was especially useful in this case, as fuel tanks are often located underground and away from the city, where a wired connection would be inefficient.

Boasting its dual SIM and auto-failover capabilities, TRB245 was the perfect fit – able to provide an uninterrupted, high-speed internet connection.

TOPOLOGY

BENEFITS

- TRB245 is sturdy and durable – perfect for remote and rugged industrial environments where wired internet is not a good fit.

- A high-speed and stable internet connection is guaranteed, even if TRB245 is installed deep underground in a hazardous environment.

- Equipped with dual SIM and auto-failover features, TRB245 keeps your connection uninterrupted.

- Being compact, simple, and easy to set up, TRB245 helps reduce infrastructure complexity and improve resource management.

- An ethernet port and multiple serial interfaces and I/Os also make it fit a variety of different needs.

TRB245

kkk

- Mobile: 4G/LTE (Cat 4), 3G, 2G

- CPU: Qualcomm, MIPS 24Kc, 650 MHz

- Memory: 16 MBytes Flash, 64 MBytes RAM

- Powering option: 16pin terminal, 9-30 VDC

- SIM: 2x Internal SIM holders (2FF)

Find out exciting news and more about our products every week at varia.org/blog !